| 2 YEAR | I semester | 6 CFU |

| (from ICT) | |

| Ernestina CIANCA | A.Y. 2023-24 |

| Code: 8039522 SSD: ING-INF/03 |

| 2 YEAR | II semester | 6 CFU |

| Patrizio Tomei (4cfu) Eugenio Martinelli (2cfu) |

A.Y. 2023-24 |

| SANTOSUOSSO Giovanni Luca | A.Y. 2024-25 |

| A.Y. 2025-26 (new name “Identification and Neural Networks” |

|

| Didatticaweb | |

| Code: 80300088 SSD: ING-INF/04 |

Pre-requirement: The basics of systems theory and control are required.

LEARNING OUTCOMES: The course aims to provide the basic techniques for the design of predictors, filters, and adaptive controllers.

KNOWLEDGE AND UNDERSTANDING: Students must obtain a detailed understanding of design techniques with the help of MATLAB-SIMULINK to solve industrial problems of adaptive filtering, adaptive prediction, and adaptive control.

APPLYING KNOWLEDGE AND UNDERSTANDING: Students must be able to apply the project techniques learned in the course even in different industrial situations than those examined in the various phases of the course.

MAKING JUDGEMENTS: Students must be able to apply the appropriate design technique to the specific cases examined, choosing the most effective algorithms.

COMMUNICATION SKILLS: Students must be able to communicate using the terminology used for filtering, prediction, and adaptive control. They must also be able to provide logical and progressive exposures starting from the basics, from structural properties, from modeling to the design of algorithms, without requiring particular prerequisites. Students are believed to be able to understand the main results of a technical publication on the course topics. Guided individual projects (which include the use of Matlab-Simulink) require assiduous participation and exchange of ideas.

LEARNING SKILLS: Students must be able to identify the appropriate techniques and algorithms in real cases that arise in industrial applications. Furthermore, it is believed that students have the ability to modify the algorithms learned during the course in order to adapt them to particular situations under consideration.

Texts

Adaptive Filtering Prediction and Control, Graham C. Goodwin, Kwai Sang Sin, Dover Publications, 2009.

| 2 YEAR | II semester | 6 CFU |

| Cristiano M. Verrelli | A.Y. 2021-22 to A.Y. 2024-25 |

|

|

A.Y. 2025-26 (new name CONTROL OF ELECTRICAL MOTORS AND VEHICLES ) |

| Code:8039782 SSD: ING-INF/04 |

LEARNING OUTCOMES: The course aims to provide a unified exposition of the most important steps and concerns in mathematical modeling and design of estimation and control algorithms for electrical machines such as:

– permanent magnet synchronous motors

– permanent magnet stepper motors

– synchronous motors with damping windings

– induction (asynchronous) motors

– synchronous generators.

KNOWLEDGE AND UNDERSTANDING: Students should be able to gain profound insight into the fundamental mathematical modeling and control design techniques for electrical machines, which are of interest and value not only to engineers engaged in the control of electric machines but also to a broader audience interested in (nonlinear) control design.

APPLYING KNOWLEDGE AND UNDERSTANDING: Students should be able to deeply understand mathematical modeling through nonlinear differential equations, stability and nonlinear control theory concepts, and design of (nonlinear) adaptive controls containing parameter estimation algorithms (important for applications). Students should be able to apply the related knowledge to learning control of robotic manipulators and cruise/yaw rate control of electric vehicles.

MAKING JUDGEMENTS: Students should be able to identify the specific design scenario and apply the most suitable techniques. Students should be able to compare the effectiveness of different controls while analyzing theoretical/experimental advantages and drawbacks.

COMMUNICATION SKILLS: Students should be able to use a single notation and modern (nonlinear) control terminology. Students should be able to exhibit a logical and progressive exposition starting from basic assumptions, structural properties, modeling, control, and estimation algorithms. Students are also expected to be able to read and capture the main results of a technical paper concerning the topics of the course, as well as to effectively communicate in a precise and clear way the content of the course. Tutor-guided individual projects (including Maple and Matlab-Simulink computer simulations and lab visits) invite intensive participation and exchanging ideas.

LEARNING SKILLS: Being enough skilled in the specific field to undertake the following studies characterized by a high degree of autonomy.

TEXTS

R. Marino, P. Tomei, C.M. Verrelli, Induction Motor Control Design, Springer, 2010.

Latest journal papers.

VERIFICATION OF THE KNOWLEDGE

Verify the knowledge and skills acquired by the student on the topics covered by the program. The intermediate exams, the final written tests, and the oral exam will consist of questions related to the topics covered by the program of the course. The questions are aimed at ascertaining the student’s knowledge and his/her reasoning skills in making logical connections between the different topics.

The final vote of the exam is expressed out of thirty and will be obtained through the following graduation system:

Not pass: important deficiencies in the knowledge and in the understanding of the topics; limited capacity for analysis and synthesis, frequent mistakes and limited critical and judgmental capacity, inconsistent reasoning, inappropriate language.

18-21: the student has acquired the basic concepts of the discipline and has an analytical capacity that comes out only with the help of the teacher. The way of speaking and the language used are almost correct, though not precise.

22-25: the student has acquired the basic concepts of the discipline in a discrete way; he/she knows how to discuss the various topics; he/she has an autonomous analysis capacity while adopting a correct language.

26-29: the student has a well-structured knowledge base. He/She is able to independently adopt a correct logical reasoning; notations and technical language are correct.

30 and 30 cum laude: the student has a complete and in-depth knowledge base. The cultural references are rich and up-to-date while being expressed by means of brilliant technical language.

| 2 YEAR | II semester | 6 CFU |

| Arianna Mencattini | A.Y. 2021-22

A.Y. 2022-23 |

| A.Y. 2023-24

Computer Vision A.Y. 24-25 |

|

| Code: 8039787 SSD: ING/INF/07 |

LEARNING OUTCOMES: Learning basic concepts in digital image processing and analysis as a novel measurement system in biomedical fields. The main algorithms will be illustrated particularly devoted to the image medical fields.

KNOWLEDGE AND UNDERSTANDING: The student acquires knowledge related to the possibility to use an image analysis platform to monitor the dynamics of a given phenomenon and to extract quantitative information from digital images such as object localization and tracking in digital videos.

APPLYING KNOWLEDGE AND UNDERSTANDING: The student acquires the capability to implement the algorithms in Matlab through dedicated lessons during the course with the aim of being able to autonomously develop new codes for the solution of specific problems in different application fields.

MAKING JUDGEMENTS: :

The student must be able to integrate the basic knowledge provided with those deriving from the other courses such as probability, signal theory, and pattern recognition. some fundamentals of measurement systems as well as basic metrological definitions will be provided in support of background knowledge.

COMMUNICATION SKILLS:

The student solves a written test and develops a project in Matlab that illustrates during the oral exam. The project can be done in a group to demonstrate working group capabilities.

LEARNING SKILLS:

Students will be able to read and understand scientific papers and books in English and also to deepen some topics. In some cases, students will develop also experimental tests with time-lapse microscopy acquisition in the department laboratory.

SYLLABUS:

Fundamentals of metrology. Basic definitions: resolution, accuracy, precision, reproducibility, and their impact over an image based measurement system. Image processing introduction. Image representation. Spatial and pixel resolution. Image restoration. Deconvolution. Deblurring. Image quality assessment. Image enhancement. Image filtering for smoothing and sharpening. Image segmentation: pixel based (otsu method), edge based, region based (region growing), model based (active contour, Hough transform), semantic segmentation. Morphological operators. Object recognition and image classification. Case study: defects detection, object tracking in biology, computer assisted diagnosis, facial expression in human computer interface.

Matlab exercises.

| 2 YEAR | 1 semester | 12 CFU |

| Patrick LONGHI (3cfu) Giancarlo ORENGO (3cfu) Gian Carlo CARDARILLI (4cfu) Luca DI NUNZIO (2cfu) |

since A.Y. 2019-20 |

| M-5519 – ELECTRONICS OF IOT (6cfu) M-5520 – DESIGN OF EMBEDDED SYSTEMS FOR MECHATRONICS (6cfu) |

|

| Code: 8039795 SSD: ING-INF/01 |

EDUCATIONAL OBJECTIVES:

The objectives of the course are:

1) to provide the tools to carry out a radio link assessment in a real application context.

2) learn the fundamental parameters of the antennas used in IoT applications

3) provide the tools to interpret the electrical diagram of the RF front end of a typical trans receiver.

KNOWLEDGE AND UNDERSTANDING:

Provide the fundamental tools to understand the most advanced and updated content from publications, magazines, forums, blogs, etc., to always be updated on the state of the art.

ABILITY TO APPLY KNOWLEDGE AND UNDERSTANDING:

Practical radio link budget, electronic noise evaluation on receiver behavior, installation effects of the antennas, understanding of key parameters of commonly used antennas in the targeted scenario, analysis of an RF transceiver block diagram

AUTONOMY OF JUDGMENT:

With the enormous amount of information that is available today to developers of IoT applications, the course seeks to develop the ability of the student to select the highest quality and most validated content.

COMMUNICATION SKILLS:

The final test is based on an oral exam in which the student illustrates a part of the module

LEARNING ABILITY:

The course aims to develop in the student the ability to independently learn new and constantly updated content because the knowledge acquired today soon becomes obsolete.

SYLLABUS:

(Longhi):

Introduction to radiating elements and their key parameters.

Ideal and practical link budget.

The effect of noise in electronic receivers, figures of merit and mathematical modelling. Receiver G/T.

Practical aspects of IoT RF systems

RFID

Radiating elements key parameters, gain, directivity, HPBW, nulls, radiation pattern, polarization, and input impedance. Some practical cases: the mono/di-pole family, microstrip antennas, parabolic reflector, wearables

Introduction to RF transceiver systems and key-components (switches, HPA, LNA, mixers, frequency generators).

(G.Orengo):

Summary of Digital Electronics: digital encoding of information, binary (fixed and floating point), hexadecimal and ASCII; operators and main logic circuits, registers and memories, programmable devices. Prototyping boards for IoT (Arduino, Rasberry), Systems on Chip (SoC), architecture of a microcontroller, description of the Arduino Uno board. Programming languages (assembly, compiled, interpreted), structure of an Arduino sketch (libraries, setups, loops, functions, interrupts), programming elements in C (variables, math and logical operations, cycles, conditional statements). Use of digital and analog I/O ports (A/D conversion, PWM output). Synchronous and asynchronous serial communication modes, wired (USB) and wireless with Bluetooth, RF and WiFi modules. Remote control of electronic modules (sensors, dc stepper and servo motors, LED/LCD displays etc.) from portable devices (Windows, IoS), through applications developed in Processing and Python, and mobile (Android), through Apps developed with the MIT App Inventor platform. Internet protocols for device local/remote control through WiFi modules connected as access points/clients to web platforms or public/private cloud servers controlled by laptops and/or mobile devices.

(G.Cardarilli):

– Introduction to the Internet of Things (IoT) and embedded systems

– Wireless and mobile communications

– The Sensors

– Low power processing

– IoT and machine learning applications

– Future developments in the field of IoT and embedded systems

| 2 YEAR |

1 semester | 9 CFU |

| Riccardo MARINO | Since 2019-20 |

| Code: 8039823 SSD: ING-INF/04 |

LEARNING OUTCOMES:

Ability to understand scientific papers on the control of mechanical systems

KNOWLEDGE AND UNDERSTANDING:

Knowledge of dynamic modeling of mechanical systems. Knowledge of basic feedback control techniques for single input single output systems and of decoupling techniques for multi input multi output nonlinear systems

APPLYING KNOWLEDGE AND UNDERSTANDING:

Ability to simulate using Matlab Simulink complex controlled mechanical systems

MAKING JUDGEMENTS:

Ability to evaluate stability, robustness, and performance of a control system

COMMUNICATION SKILLS: Ability to present and discuss an autonomous design project

LEARNING SKILLS: Ability to fully understand a scientific paper on the control of mechanical systems

SYLLABUS:

BASIC CONTROL TOOLS

Bounded- input bounded- output linear systems. Pole placement theorem for controllable and observable linear systems. Luenberger observers for observable systems. Design of dynamic compensators for linear systems. Integral feedback control to reject constant disturbances. PID control. System inverses for minimum phase linear systems. The combination of feedback and feedforward control actions.

ADVANCED CONTROL TOOLS

Linear approximations of nonlinear control systems about operating conditions. The definition of region of attraction for an operating condition. Output feedback compensators with integral actions to control nonlinear systems about a given operating condition. Liapunov matrix equations to determine quadratic Liapunov functions and assess the region of attraction. The definition of the sensitivity transfer function and its properties. The gang of four: sensitivity, complementary sensitivity, load sensitivity and noise sensitivity functions. How to determine the robustness of a control loop using the gang of four functions. Bode’s integral formula and the limitations imposed by unstable open loop poles. Youla parametrization to design stable compensation. Kalman filters, Riccati equations and robust control design.

CONTROL DESIGN FOR MULTIVARIABLE NONLINEAR SYSTEMS

Relative degree for a single input single output nonlinear system. State feedback control design for input-output linearization. State feedback linearization when the relative degree is equal to the state space dimension. The definition of nonlinear inverse systems. Relative degrees or decoupling indices for multivariable (multi-input, multi-output) nonlinear systems. The definition of the decoupling matrix. State feedback control design for input-output linearization when the decoupling matrix is full rank using the Penrose pseudoinverse. State feedback linearization when the sum of relative degrees is equal to the state space dimension and the decoupling matrix is full rank.

CASE STUDIES OF NONLINEAR MECHANICAL CONTROL SYSTEMS

Control of bycicles, robots, vehicles and aircrafts

| 2 YEAR | II semester | 6 CFU |

| Luciano CANTONE | since A.Y. 2018-19 |

| (by Engineering Sciences) | |

| Code: 80300065 SSD:ING-IND/14 |

LEARNING OUTCOMES: Designing mechanical components considering the need to save weight, material and energy while respecting safety, to promote the usefulness and social impact of the designed product.

KNOWLEDGE AND UNDERSTANDING: The design of mechanical systems, in particular, basic knowledge of the design methodologies of important machine components.

APPLYING KNOWLEDGE AND UNDERSTANDING: Know how to recognise, distinguish, and use the main techniques and tools to design mechanical components.

MAKING JUDGEMENTS: Students must assume the missing data of a problem and be able to independently formulate basic hypotheses (such as that on safety coefficients) based on the operational and functional context of the system/component they have to design.

COMMUNICATION SKILLS: Transfer information, ideas and solutions to specialist and non-specialist interlocutors through intensive use of English terminology.

LEARNING SKILLS: Students, by learning the basics of design, acquire the tools to learn the necessary design techniques of systems/components not directly addressed during the course.

VERIFICATION CRITERIA

Solution of the assignments given during the teaching. The written exam consists of 4 exercises, similar to those solved during the lessons. After passing the written test, there is an oral examination with two questions. The student’s evaluation is related to the understanding and mastery of the principles and methods of design for both written and oral exams.

The oral exam questions aim to ascertain the student’s knowledge and reasoning skills in connecting the different topics covered within the course.

The final vote of the exam is expressed out of thirty and follows the next graduation system:

Not pass, essential deficiencies in the knowledge and understanding of the topics; limited capacity for analysis and synthesis, frequent generalizations and limited critical and judgmental capacity, the topics are set out inconsistently and with inappropriate language

18-21, the student has acquired the basic concepts of the discipline and has an analytical capacity that emerges only with the teacher’s help. The way of speaking and the language used are, on the whole, correct.

22-25, the student has acquired the basic concepts of the discipline discreetly, knows how to orient himself or herself among the various topics covered and has an autonomous analysis capacity that knows how to express with the correct language.

26-29, the student has a well-structured knowledge base. He/She can independently rework the knowledge acquired in the context of the choice of conventional and unconventional materials according to the application; the way of speaking and the technical language are correct.

30 and 30 cum laude, the student has a complete and in-depth knowledge base. The cultural references are rich and up-to-date, expressed with brilliance and properties of technical language.

The midterm tests are optional and allow you to avoid the oral examination with an overall mark of at least 18/30.

Syllabus

Consolidation of basic knowledge to put the student in the right conditions to face a generic machine design problem: Mechanical Engineering design in Broad, Perspective, Load Analysis, Materials, Static Body Stresses, Elastic strain, Deflection, Stability (Eulerian buckling), Vibrations (beam Eigen-modes), Failure Theories,Safety Factors, Reliability, High cycles Fatigue, Low cycles Fatigue, Surface Damage, Contact and impact problems. During the course, several design activities will be demonstrated by exercises and by real life applications.

TEXTS

Machine Component Design, 7th Edition International Student Version Robert C. Juvinall – (University of Michigan), Kurt M. Marshek (University of Texas at Austin)

Teacher’s slides

| 1 YEAR (Block C)

2 YEAR (Blocks A|B|D|E) |

II semester | 9 CFU |

| Stefano CORDINER (6/9 cfu) Lorenzo BARTOLUCCI (3/9 cfu) |

A.Y. 2021-22

Internal Combustion Engines |

| Since A.Y. 2022-23

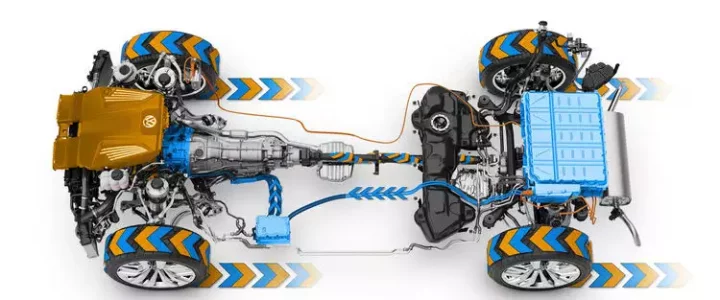

POWERTRAIN TECHNOLOGIES FOR FUTURE MOBILITY |

|

| Code: 80300079

80300077 M-6264 |

PREREQUISITES: Technical Physics, Fluid Machinery

FORMATIVE OBJECTIVES

LEARNING OUTCOMES:

The course aims to provide students with in-depth scientific training to correctly address the problems of designing, choosing and managing new propulsion systems for sustainable mobility starting from current solutions with internal combustion engines as well as creating the conditions for the development of innovative and low environmental impact solutions. To this end, students will develop in-depth knowledge of the operating principles of propulsion systems for transport and will learn simulation procedures for their verification and sizing. Finally, particular attention is dedicated to the most recent technological development of internal combustion engine technology aimed at overcoming current limits in terms of emissions and efficiency and defining innovative scenarios for sustainable mobility.

KNOWLEDGE AND UNDERSTANDING:

Course aim is to provide the students with tools for the analysis of the performances and the evaluation of proper design solution for internal combustion engines and their core components. At the end of the course, the student will be able to independently understand the functional link between design variables and the performance of internal combustion engines also in case of innovative design,

APPLYING KNOWLEDGE AND UNDERSTANDING:

The course, through the analysis of specific problems and quantitative data, is aimed at providing the tools for analysis and evaluation of the effects of different design choices. The theme of energy efficiency and pollution reduction are at the heart of the teaching organization. The student will be able to interpret and propose design solutions, even innovative ones, adapted to the specificity of the problems that are presented to him.

MAKING JUDGEMENTS:

By studying theoretical and practical aspects of engine design and critically assessing the influence of different design variables, the student will be able to improve his judgment and proposal in relation to design. and the management of internal combustion engines.

COMMUNICATION SKILLS:

The presentation of the theoretical and application profiles underlying the operation of internal combustion engines will be carried out to allow the knowledge of the technical language of the appropriate specialist terminology; The development of communication skills, both oral and written will also be stimulated through classroom discussion, participation in seminary activities and through final tests.

LEARNING SKILLS:

The learning capacity, even individual, will be stimulated through numerical exercises, the drafting of papers on specialized topics, the discussion in the classroom, also aimed at verifying the actual understanding of the topics treated. The learning capacity will also be stimulated by integrative educational aids (journal articles and economic newspapers) in order to develop autonomous application capabilities.

SYLLABUS:

Legislation evolution on Internal Combustin Engines. Definition of the performance of the propulsion systems and their operating characteristics in relation to the mission, driving cycles. Generalities on reciprocating internal combustion engines: Characteristics and classification, thermodynamic and performance analysis of reciprocating internal combustion engines.

Air supply for 4-stroke engines: volumetric efficiency and its evaluation; Design elements of intake systems: quasi-stationary effects; valve sizing; influence of other engine parameters; Variable Valve Actuation systems. 2-stroke engines: construction schemes; Non-stationary phenomena in intake and exhaust ducts: inertia and wave propagation; variable geometry systems; calculation models; Supercharging.

In cylinder charge Motion: Turbulence; swirl, squish, tumble; stratified charge engines.

Traditional and alternative fuels; Properties of motor fuels. Generalities: combustibles; stoichiometric air; calorific value Gaseous fuels: natural gas, hydrogen and mixtures. bio-ethanol, bio-diesel and DME. Characteristics and their use in engines: technical solutions, performance and emissions.

Fuel supply Premixed combustion engines; Non-pre-mixed combustion engines.

Combustion : Analytical elements of combustion; thermodynamics of combustion processes; calculation of the chemical composition and of the adiabatic equilibrium temperature ; transport phenomena ; chemical kinetics.

Pollutant emissions and abatement systems; Emissions: formation mechanisms, effects on health and the environment, measurement of emissions; influence of engine parameters; Innovative combustion solutions, Advanced Thermodynamic Cycles. Sustainable mobility. Operating principles of hybrid vehicles: series and parallel solution; motors a.c. and electrical employees; regenerative braking; lithium batteries, performance and prospects. Plug-in hybrid vehicles, i.c. engines “range extender”. Innovative control logics for optimal powersplitting between the different energy sources. Electric vehicles, characteristics and prospects. Numerical simulation tools will be presented for all course topics

ATTENDANCE

Course attendance is strongly recommended. During the course, students are invited to interact with the Professor during the class or office hours for any clarification or insight in specific topics related to the program.

| 2 YEAR | 2 semester | 9 CFU |

| Stefano Bifaretti |

A.Y. 2021-22 |

| Stefano Bifaretti (7cfu)

Cristina Terlizzi (2cfu) |

A.Y. 2022-23 1st Year I semester A.Y. 2023-24 (NOT HELD)A.Y. 2024-25 |

| Stefano Bifaretti | A.Y. 2025-26 |

| Code: 8039781 SSD: ING-INF/01 |

LEARNING OUTCOMES:

The Power Electronics and Electrical Drives course aims to provide a basic understanding of the power semiconductors of the main electronic circuits used for the static conversion of electrical energy as well as the electrical drives. The student will acquire the ability to analyse and perform an initial sizing of power electronic converters operating in either direct or alternating current.

KNOWLEDGE AND UNDERSTANDING:

The student will be gradually guided to the knowledge of the functional characteristics and behavior of the main static power converters used, in particular, in industrial applications, in Distributed Generation Systems and in power trains of electical vehicles. In order to improve the topics understanding, the use of Matlab-Simulink specific packages for the simulation of electronic power converters is illustrated.

APPLYING KNOWLEDGE AND UNDERSTANDING:

The knowledge acquired during the course allows the student to select the topology and size of the power converter in relation to the final design.

Different application examples, in particular devoted to distributed energy generation plants, uninterruptible power supplies and electric mobility will allow the student to improve his ability to apply the acquired knowledge.

MAKING JUDGEMENTS:

The student will be able to collect and process specialized technical information on power converters and verify their validity.

COMMUNICATION SKILLS:

The student will be able to relate with power electronics specialists in order to request the technical information necessary for the development of a project activity.

LEARNING SKILLS:

The skills acquired during the course will allow the student to undertake, with a high degree of autonomy, subsequent studies or apply for technical roles in companies working in the field.

SYLLABUS:

POWER SEMICONDUCTORS

Power Semiconductors employed in Power Electronics converters: Diodes, BJT, MOSFET, IGBT, Thyristors, Wide Bandgap Semiconductors).

Static and dynamic behavior. Thermal behavior. Conduction and switching losses.

Technical specifications provided by manufacturers’ datasheets. Driving circuits.

POWER CONVERTER TOPOLOGIES

Behavioral characteristics: unidirectional and bidirectional energy transfer, controlled voltage sources. Analysis method of power converters.

DC-DC Converters. Buck, Boost, Buck-Boost. Switching losses reduction. Average Model. Modulation techniques (PWM, PFM, PRM). Output voltage open-loop control. Closed-loop control. Current control.Half and Full Bridge DC-DC converters.

DC-AC Converters (Inverters). Half and Full Bridge DC-AC single-phase converters based on static switches. Three-phase converters. Modulation techniques. Selective Harmonic Elimination (SHE). Sinusoidal Pulse Width Modulation (SPWM).

Rectifiers: Single-phase and three-phase diode rectifiers. Single-phase and three-phase force-commutated PWM rectifiers: topologies, voltage and current controls. Power Factor Corrector (PFC). Effects on grid side of power converters. Generalized power factor. Compliance with grid codes.

Isolated DC-DC converter.

ELECTRICAL DRIVES

Introduction to Electrical Drives. DC, Permanent Magnet Synchronous Motors and Induction Motors. DC motors model.

Power Electronics Applications

Power Converters simulation using Matlab-Simulink/Simpowersystem.

Photovoltaic Conversion Systems.

Power trains for electrical vehicles. Battery chargers.

| 1 YEAR (Blocks B|C) 2 YEAR (Blocks A|D|E) |

1 semester | 9 CFU |

| Marco Ceccarelli (6/9 cfu)

Matteo Russo (3/6 cfu) |

A.Y. 2021-22

A.Y. 2022-23 |

| Matteo Russo (9cfu) |

A.Y. 2023-24 A.Y. 2024-25 |

| Code: 8039785 SSD: ING-IND/13 |

LEARNING OUTCOMES: This course will provide students with the knowledge and tools needed to model and analyse robotic manipulators in terms of mechanical performance. Students will learn how to design, evaluate, and control industrial and service robots.

KNOWLEDGE AND UNDERSTANDING: The student will learn to analyse robotic systems by modelling their kinematics and dynamics and thus finding their key operational parameters. Furthermore, the student will learn how to design a manipulator from its operational requirements, such as workspace, velocity, and payload.

APPLYING KNOWLEDGE AND UNDERSTANDING: The student will apply this knowledge to design, model, and evaluate robots with examples of use cases. Once identified the joints and bodies that compose a robot, the student will be able to numerically characterize its operation and mobility. Furthermore, the student will be able to critically select a robot type for a given manipulation task.

MAKING JUDGEMENTS: The student will demonstrate their understanding of robot operation by developing and presenting a practical use case, in which they will examine autonomously and critically the challenges behind robot design and application.

COMMUNICATION SKILLS: During the course, students discuss key topics, working on a written project on manipulation analysis of their own choice. Project results are then presented at the end of the course.

LEARNING SKILLS: During the course, students are involved in the lecture for a continuous stimulus to verify their understanding of robot mechanics. The knowledge acquired during the course is also verified in the final project on manipulation analysis.

REQUIREMENTS: The student should have already attended the fundamental courses on calculus, geometry, and physics. The understanding of rigid body mechanics and basic programming skills (MATLAB) are required, as well as knowledge of mechanism design and analysis.

PROGRAMME:

EXAM:

The exam is divided into a written and oral test. The written test consists of three exercises regarding practical use-cases of industrial and service robots. In alternative, a project report developed during the course can be evaluated. In the oral test, the student will discuss with a critical perspective robot functioning. In alternative, the developed project on manipulation analysis can be presented and discussed.