| 2 YEAR | II semester | 9 CFU |

| Stefano CORDINER (6/9 cfu) Lorenzo BARTOLUCCI (3/9 cfu) |

A.Y. 2021-22

Internal Combustion Engines |

| Since A.Y. 2022-23 – program 📑

POWERTRAIN TECHNOLOGIES FOR FUTURE MOBILITY |

|

| Code: 80300079

80300077 M-6264 |

PREREQUISITES: Technical Physics, Fluid Machinery

FORMATIVE OBJECTIVES

LEARNING OUTCOMES:

The course aims to provide students with in-depth scientific training to correctly address the problems of designing, choosing and managing new propulsion systems for sustainable mobility starting from current solutions with internal combustion engines as well as creating the conditions for the development of innovative and low environmental impact solutions. To this end, students will develop in-depth knowledge of the operating principles of propulsion systems for transport and will learn simulation procedures for their verification and sizing. Finally, particular attention is dedicated to the most recent technological development of internal combustion engine technology aimed at overcoming current limits in terms of emissions and efficiency and defining innovative scenarios for sustainable mobility.

KNOWLEDGE AND UNDERSTANDING:

Course aim is to provide the students with tools for the analysis of the performances and the evaluation of proper design solution for internal combustion engines and their core components. At the end of the course, the student will be able to independently understand the functional link between design variables and the performance of internal combustion engines also in case of innovative design,

APPLYING KNOWLEDGE AND UNDERSTANDING:

The course, through the analysis of specific problems and quantitative data, is aimed at providing the tools for analysis and evaluation of the effects of different design choices. The theme of energy efficiency and pollution reduction are at the heart of the teaching organization. The student will be able to interpret and propose design solutions, even innovative ones, adapted to the specificity of the problems that are presented to him.

MAKING JUDGEMENTS:

By studying theoretical and practical aspects of engine design and critically assessing the influence of different design variables, the student will be able to improve his judgment and proposal in relation to design. and the management of internal combustion engines.

COMMUNICATION SKILLS:

The presentation of the theoretical and application profiles underlying the operation of internal combustion engines will be carried out to allow the knowledge of the technical language of the appropriate specialist terminology; The development of communication skills, both oral and written will also be stimulated through classroom discussion, participation in seminary activities and through final tests.

LEARNING SKILLS:

The learning capacity, even individual, will be stimulated through numerical exercises, the drafting of papers on specialized topics, the discussion in the classroom, also aimed at verifying the actual understanding of the topics treated. The learning capacity will also be stimulated by integrative educational aids (journal articles and economic newspapers) in order to develop autonomous application capabilities.

SYLLABUS:

Legislation evolution on Internal Combustin Engines. Definition of the performance of the propulsion systems and their operating characteristics in relation to the mission, driving cycles. Generalities on reciprocating internal combustion engines: Characteristics and classification, thermodynamic and performance analysis of reciprocating internal combustion engines.

Air supply for 4-stroke engines: volumetric efficiency and its evaluation; Design elements of intake systems: quasi-stationary effects; valve sizing; influence of other engine parameters; Variable Valve Actuation systems. 2-stroke engines: construction schemes; Non-stationary phenomena in intake and exhaust ducts: inertia and wave propagation; variable geometry systems; calculation models; Supercharging.

In cylinder charge Motion: Turbulence; swirl, squish, tumble; stratified charge engines.

Traditional and alternative fuels; Properties of motor fuels. Generalities: combustibles; stoichiometric air; calorific value Gaseous fuels: natural gas, hydrogen and mixtures. bio-ethanol, bio-diesel and DME. Characteristics and their use in engines: technical solutions, performance and emissions.

Fuel supply Premixed combustion engines; Non-pre-mixed combustion engines.

Combustion : Analytical elements of combustion; thermodynamics of combustion processes; calculation of the chemical composition and of the adiabatic equilibrium temperature ; transport phenomena ; chemical kinetics.

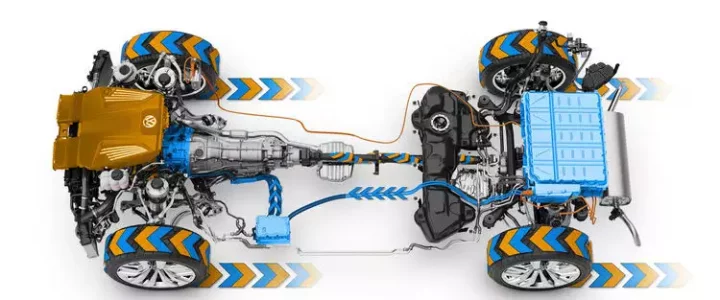

Pollutant emissions and abatement systems; Emissions: formation mechanisms, effects on health and the environment, measurement of emissions; influence of engine parameters; Innovative combustion solutions, Advanced Thermodynamic Cycles. Sustainable mobility. Operating principles of hybrid vehicles: series and parallel solution; motors a.c. and electrical employees; regenerative braking; lithium batteries, performance and prospects. Plug-in hybrid vehicles, i.c. engines “range extender”. Innovative control logics for optimal powersplitting between the different energy sources. Electric vehicles, characteristics and prospects. Numerical simulation tools will be presented for all course topics

ATTENDANCE

Course attendance is strongly recommended. During the course, students are invited to interact with the Professor during the class or office hours for any clarification or insight in specific topics related to the program.

UNIVERSITA' DEGLI STUDI ROMA "TOR VERGATA"

UNIVERSITA' DEGLI STUDI ROMA "TOR VERGATA"