| 1 YEAR | I semester | 6 CFU |

| (from ICT) | |

| Ernestina CIANCA | A.Y. 2023-24

📑

|

| Code: 8039522 SSD: ING-INF/03 |

| 1 YEAR | I semester | 6 CFU |

| (from ICT) | |

| Ernestina CIANCA | A.Y. 2023-24

Teaching programs (Schede d’Insegnamento-GOMP)📑

|

| Code: 8039522 SSD: ING-INF/03 |

| 2 YEAR | 1 semester | 12 CFU |

| Patrick LONGHI (3cfu) Giancarlo ORENGO (3cfu) Gian Carlo CARDARILLI (4cfu) Luca DI NUNZIO (2cfu) |

since A.Y. 2019-20 |

| M-5519 – ELECTRONICS OF IOT (6cfu) M-5520 – DESIGN OF EMBEDDED SYSTEMS FOR MECHATRONICS (6cfu) |

|

| Code: 8039795 SSD: ING-INF/01 |

EDUCATIONAL OBJECTIVES:

The objectives of the course are:

1) to provide the tools to carry out a radio link assessment in a real application context.

2) learn the fundamental parameters of the antennas used in IoT applications

3) provide the tools to interpret the electrical diagram of the RF front end of a typical trans receiver.

KNOWLEDGE AND UNDERSTANDING:

Provide the fundamental tools to understand the most advanced and updated content from publications, magazines, forums, blogs, etc., to always be updated on the state of the art.

ABILITY TO APPLY KNOWLEDGE AND UNDERSTANDING:

Practical radio link budget, electronic noise evaluation on receiver behavior, installation effects of the antennas, understanding of key parameters of commonly used antennas in the targeted scenario, analysis of an RF transceiver block diagram

AUTONOMY OF JUDGMENT:

With the enormous amount of information that is available today to developers of IoT applications, the course seeks to develop the ability of the student to select the highest quality and most validated content.

COMMUNICATION SKILLS:

The final test is based on an oral exam in which the student illustrates a part of the module

LEARNING ABILITY:

The course aims to develop in the student the ability to independently learn new and constantly updated content because the knowledge acquired today soon becomes obsolete.

SYLLABUS:

(Longhi):

Introduction to radiating elements and their key parameters.

Ideal and practical link budget.

The effect of noise in electronic receivers, figures of merit and mathematical modelling. Receiver G/T.

Practical aspects of IoT RF systems

RFID

Radiating elements key parameters, gain, directivity, HPBW, nulls, radiation pattern, polarization, and input impedance. Some practical cases: the mono/di-pole family, microstrip antennas, parabolic reflector, wearables

Introduction to RF transceiver systems and key-components (switches, HPA, LNA, mixers, frequency generators).

(G.Orengo):

Summary of Digital Electronics: digital encoding of information, binary (fixed and floating point), hexadecimal and ASCII; operators and main logic circuits, registers and memories, programmable devices. Prototyping boards for IoT (Arduino, Rasberry), Systems on Chip (SoC), architecture of a microcontroller, description of the Arduino Uno board. Programming languages (assembly, compiled, interpreted), structure of an Arduino sketch (libraries, setups, loops, functions, interrupts), programming elements in C (variables, math and logical operations, cycles, conditional statements). Use of digital and analog I/O ports (A/D conversion, PWM output). Synchronous and asynchronous serial communication modes, wired (USB) and wireless with Bluetooth, RF and WiFi modules. Remote control of electronic modules (sensors, dc stepper and servo motors, LED/LCD displays etc.) from portable devices (Windows, IoS), through applications developed in Processing and Python, and mobile (Android), through Apps developed with the MIT App Inventor platform. Internet protocols for device local/remote control through WiFi modules connected as access points/clients to web platforms or public/private cloud servers controlled by laptops and/or mobile devices.

(G.Cardarilli):

– Introduction to the Internet of Things (IoT) and embedded systems

– Wireless and mobile communications

– The Sensors

– Low power processing

– IoT and machine learning applications

– Future developments in the field of IoT and embedded systems

| 2 YEAR |

1 semester | 9 CFU |

| Riccardo MARINO | Since 2019-20 |

| Teaching programs (Schede d’Insegnamento-GOMP)📑

Code: 8039823 |

LEARNING OUTCOMES:

Ability to understand scientific papers on the control of mechanical systems

KNOWLEDGE AND UNDERSTANDING:

Knowledge of dynamic modeling of mechanical systems. Knowledge of basic feedback control techniques for single input single output systems and of decoupling techniques for multi input multi output nonlinear systems

APPLYING KNOWLEDGE AND UNDERSTANDING:

Ability to simulate using Matlab Simulink complex controlled mechanical systems

MAKING JUDGEMENTS:

Ability to evaluate stability, robustness, and performance of a control system

COMMUNICATION SKILLS: Ability to present and discuss an autonomous design project

LEARNING SKILLS: Ability to fully understand a scientific paper on the control of mechanical systems

SYLLABUS:

BASIC CONTROL TOOLS

Bounded- input bounded- output linear systems. Pole placement theorem for controllable and observable linear systems. Luenberger observers for observable systems. Design of dynamic compensators for linear systems. Integral feedback control to reject constant disturbances. PID control. System inverses for minimum phase linear systems. The combination of feedback and feedforward control actions.

ADVANCED CONTROL TOOLS

Linear approximations of nonlinear control systems about operating conditions. The definition of region of attraction for an operating condition. Output feedback compensators with integral actions to control nonlinear systems about a given operating condition. Liapunov matrix equations to determine quadratic Liapunov functions and assess the region of attraction. The definition of the sensitivity transfer function and its properties. The gang of four: sensitivity, complementary sensitivity, load sensitivity and noise sensitivity functions. How to determine the robustness of a control loop using the gang of four functions. Bode’s integral formula and the limitations imposed by unstable open loop poles. Youla parametrization to design stable compensation. Kalman filters, Riccati equations and robust control design.

CONTROL DESIGN FOR MULTIVARIABLE NONLINEAR SYSTEMS

Relative degree for a single input single output nonlinear system. State feedback control design for input-output linearization. State feedback linearization when the relative degree is equal to the state space dimension. The definition of nonlinear inverse systems. Relative degrees or decoupling indices for multivariable (multi-input, multi-output) nonlinear systems. The definition of the decoupling matrix. State feedback control design for input-output linearization when the decoupling matrix is full rank using the Penrose pseudoinverse. State feedback linearization when the sum of relative degrees is equal to the state space dimension and the decoupling matrix is full rank.

CASE STUDIES OF NONLINEAR MECHANICAL CONTROL SYSTEMS

Control of bycicles, robots, vehicles and aircrafts

| 1 YEAR | I semester | 6 CFU |

| Marco Re |

since A.Y. 2021-25 |

| A.Y. 2025-26

Teaching programs (Schede d’Insegnamento-GOMP)📑

|

|

| Didatticaweb

Code: 80300061 |

| 1 YEAR |

1 semester | 6 CFU |

| Marco Ceccarelli | A.Y. 2021-22 to 2024-25

A.Y. 2025-26 new name: 80300216 MECHANICS OF SYSTEMS FOR SIMULATIONS |

| Code: 803000062 SSD: ING-IND-13 (by Engineering Sciences) |

OBJECTIVES

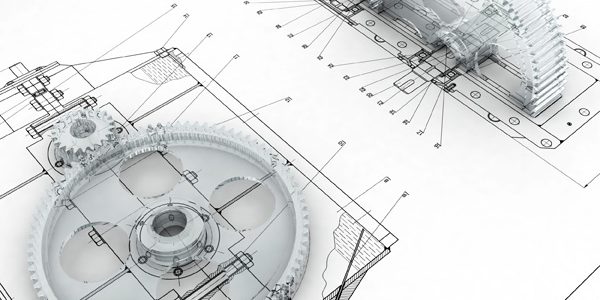

LEARNING OUTCOMES: The course aims to teach students the knowledge and tools that are needed to address the issues that are related to the identification, modeling, analysis, and design of multi-body planar systems in English language and terminology

KNOWLEDGE AND UNDERSTANDING: modeling and procedures to recognize the structure and characteristics of mechanisms and machines

APPLYING KNOWLEDGE AND UNDERSTANDING: acquisition of analysis procedures for the understanding of kinematic and dynamic characteristics of mechanisms and machines

MAKING JUDGEMENTS: possibility of judging the functionality of mechanisms and machines with their own qualitative and quantitative assessments

COMMUNICATION SKILLS: learning technical terminology and procedures for presenting the performance of mechanisms

LEARNING SKILLS: learning technical terminology and procedures for the presentation of the performance of mechanisms

PREREQUISITES: knowledge of basic mechanics of rigid bodies and computation skills

SYLLABUS

Structure and classification of planar mechanical systems, kinematic modeling, mobility analysis, graphical approaches of kinematics analysis, kinematic analysis with computer-oriented algorithms; dynamics and statics modeling, graphical approaches of dynamics analysis, dynamic analysis with computer-oriented algorithms, performance evaluation; elements of mechanical transmissions.

BOOKS:

Lopez-Cajùn C., Ceccarelli M., Mecanismos, Trillas, Città del Messico

Shigley J.E., Pennock G.R., Uicker J.J., “Theory of Machines and Mechanisms”, McGraw-Hill, New York

Handnotes and papers by the teachers

| 1 YEAR (Blocks B|C)24-25 2 YEAR (Blocks A|D|E)24-25 (All)25-26 |

1 semester | 9 CFU |

| Marco Ceccarelli (6/9 cfu)

Matteo Russo (3/6 cfu) |

A.Y. 2021-22

A.Y. 2022-23 |

| Matteo Russo (9cfu) |

since A.Y. 2023-24 – program |

| Code: 8039785 SSD: ING-IND/13 |

LEARNING OUTCOMES: This course will provide students with the knowledge and tools needed to model and analyse robotic manipulators in terms of mechanical performance. Students will learn how to design, evaluate, and control industrial and service robots.

KNOWLEDGE AND UNDERSTANDING: The student will learn to analyse robotic systems by modelling their kinematics and dynamics and thus finding their key operational parameters. Furthermore, the student will learn how to design a manipulator from its operational requirements, such as workspace, velocity, and payload.

APPLYING KNOWLEDGE AND UNDERSTANDING: The student will apply this knowledge to design, model, and evaluate robots with examples of use cases. Once identified the joints and bodies that compose a robot, the student will be able to numerically characterize its operation and mobility. Furthermore, the student will be able to critically select a robot type for a given manipulation task.

MAKING JUDGEMENTS: The student will demonstrate their understanding of robot operation by developing and presenting a practical use case, in which they will examine autonomously and critically the challenges behind robot design and application.

COMMUNICATION SKILLS: During the course, students discuss key topics, working on a written project on manipulation analysis of their own choice. Project results are then presented at the end of the course.

LEARNING SKILLS: During the course, students are involved in the lecture for a continuous stimulus to verify their understanding of robot mechanics. The knowledge acquired during the course is also verified in the final project on manipulation analysis.

REQUIREMENTS: The student should have already attended the fundamental courses on calculus, geometry, and physics. The understanding of rigid body mechanics and basic programming skills (MATLAB) are required, as well as knowledge of mechanism design and analysis.

PROGRAMME:

EXAM:

The exam is divided into a written and oral test. The written test consists of three exercises regarding practical use-cases of industrial and service robots. In alternative, a project report developed during the course can be evaluated. In the oral test, the student will discuss with a critical perspective robot functioning. In alternative, the developed project on manipulation analysis can be presented and discussed.

| 1 YEAR (ALL) 25-26 2 YEAR (Block B)24-25 |

1 semester | 9 CFU |

| Corrado Di Natale | A.Y. 2019-20 (new name, ex Electronic Devices and Sensors) |

| Alexandro Catini (6cfu) Corrado Di Natale (3cfu) |

A.Y. 2022-23 A.Y. 2023-24 |

| Alexandro Catini (8cfu) – catini@ing.uniroma2.it Corrado Di Natale (1cfu) |

A.Y. 2024-25 – program |

| Code: 8039927 SSD: ING-INF/01 |

| 1 YEAR | 1 semester | 6 CFU |

| TATA MARIA ELISA (1cfu) COSTANZA GIROLAMO (1cfu) VARONE ALESSANDRA (4cfu) |

A.Y. 2020-21 to A.Y. 2024-25 (B-C1-E) |

| COSTANZA GIROLAMO (4cfu)

TATA MARIA ELISA (2cfu) |

A.Y. 2025-26 (C1-E) |

| Code: 8039786 SSD: ING-IND/21 |

LEARNING OUTCOMES:

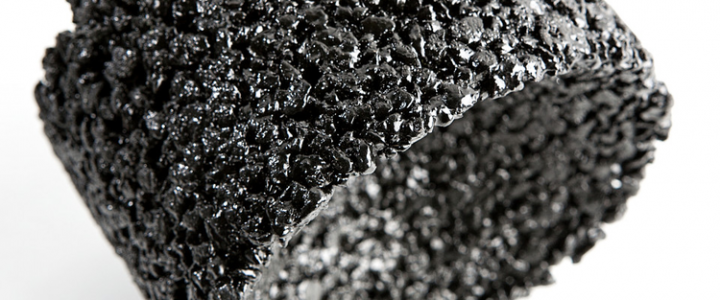

The aim of the course is to provide an overview of novel materials recently developed and investigated for applications in mechanics, electronics, and mechatronics. Different types of materials are considered and described with particular attention on the preparation route, specific characteristics, and applications. Some of them are of basic importance for new technologies gaining increasing attention in industrial practice. The knowledge of innovative materials is strictly connected to the possibility and capability of designing new products.

KNOWLEDGE AND UNDERSTANDING:

Deep knowledge of the metallic structure and their mechanical behavior; in particular knowledge of innovative materials for mechatronics applications; selection of conventional material or not as a function of application, structure and properties.

APPLYING KNOWLEDGE AND UNDERSTANDING:

Ability to define materials properties and the most suitable production technologies for the components realization; Ability to perform tests in laboratory; Ability to define appropriate treatments in order to obtain the suitable mechanical properties as a function of service conditions. Ability to select innovative materials; ability to evaluate innovative materials properties.

MAKING JUDGEMENTS:

Ability to investigate, select and choose metallic materials as a function of the application.

COMMUNICATION SKILLS:

Clear and correct expression, in English language, skills on the topics covered in the course.

LEARNING SKILLS:

Ability to face a new problem, know how to manage it and find functional and correct solutions. learning ability will be evaluated by exam tests and laboratory activities.

SYLLABUS:

Metallurgy Fundamentals: crystal structure, defects, plastic deformation. Mechanical tests.

Amorphous alloys: production and applications of metallic glasses as mechatronic devices. Alloys with mixed structure (nanocrystalline and amorphous).

Ultrafine grained (UFG) materials: microstructural features and production routes.

Nanoporous and mesoporous materials: structural characterization and properties. Their applications for energy and gas storage.

Powder metallurgy, Additive Manufacturing Technologies.

Advanced composite materials: properties, applications and production routes.

Porous materials: metal foams, Open and closed porosity (micro and macro). Classification according to size and shape of the pores. Properties (sound, energy and vibration absorption, crash

behavior) and production methods. Functional and structural

applications: lightweight construction, automotive. Metal sandwich structures.

Functional and Smart Materials. Property change as a response of external stimulus: shape memory alloy (one-way and two-way shape memory), thermochromic, photomechanical. Energy conversion: piezoelectric, thermoelectric. Phase change materials.

Applications: mechatronic, energy. Functionally graded materials.